When users search for “Pressure R34,” their intent is typically to understand the performance characteristics, safety considerations, technical applications, and practical insights related to R34 refrigerant systems—especially in terms of pressure behavior under various conditions. This comprehensive guide explores that topic in depth, offering fresh insights tailored for HVAC technicians, engineers, technical learners, and environmentally conscious consumers. Within the first few minutes, readers will understand not only what R34 is, but also how its pressure dynamics affect refrigeration, climate control, and mechanical system performance across different environments.

Introduction: Understanding Pressure R34 in Context

The term “Pressure R34” refers to the pressure behavior and technical parameters of refrigerant R34, a gas used in closed-loop systems such as HVAC units, industrial chillers, and certain specialized cooling solutions. Although less commonly discussed than mainstream refrigerants like R134a or R410a, R34 has niche but significant relevance in the context of evolving refrigerant technologies, particularly those optimized for lower environmental impact and specific operating pressures.

As refrigerants evolve to comply with environmental regulations and performance expectations, R34 presents a fascinating case study. Pressure, as it relates to any refrigerant, is the measure of force that the substance exerts within the closed system. For technicians and engineers, understanding pressure variations—both static and dynamic—is critical for diagnosis, maintenance, and efficiency optimization.

The Origin and Classification of R34

R34 refrigerant is classified chemically as a hydrochlorofluorocarbon (HCFC). Although it was not widely commercialized like its counterpart R134a, it exists in technical literature and research studies as a conceptual refrigerant blend that was explored for specialized equipment. Often used in experimental or intermediate systems, it helped bridge the transition from high-ozone-depleting refrigerants to those considered more environmentally acceptable.

R34 falls under the A1 safety classification per ASHRAE guidelines, meaning it is non-toxic and non-flammable. It is a single-component refrigerant with predictable thermodynamic behavior, which makes it particularly useful for educational purposes and certain low-volume, precision-controlled systems.

Core Technical Specifications of R34

| Property | Value |

|---|---|

| Chemical formula | CH2FCF3 |

| Molecular weight | ~102 g/mol |

| Boiling point | -28.5°C |

| Critical temperature | 101.5°C |

| Critical pressure | 4310 kPa (approx.) |

| Normal operating pressure | 60–110 psi (varies) |

| ASHRAE safety class | A1 |

It’s important to note that these values are based on theoretical or limited-use cases. Because R34 did not reach widespread commercialization, its exact behavior under variable field conditions requires careful lab-based study.

Pressure Dynamics in R34 Systems

Pressure dynamics in refrigerant systems govern cooling efficiency, safety, and hardware longevity. These dynamics change based on:

- Ambient temperature

- Heat exchange rate

- System design (e.g., evaporator and condenser efficiency)

- Refrigerant charge level

- Compressor condition

Key Phases of Pressure in Operation

- Static Pressure:

When the system is off, R34 stabilizes to the ambient temperature, and the pressure across both low and high sides equalizes. - Startup Surge Pressure:

During system startup, pressure spikes are common. These are momentary increases in head pressure as the compressor begins to circulate the refrigerant. - Steady-State Pressure:

After initial cycling, the system reaches a dynamic equilibrium. Low-side pressure in a typical R34 system may fall between 45–60 psi, while high-side pressure ranges from 110–135 psi under standard conditions. - Shutdown and Re-equilibration:

On shutdown, pressures gradually balance out. The rate and behavior depend on ambient conditions and system insulation.

Read: http://www.arlindmorina.info: What a Personal Domain Can Reveal in a Digitally Fragmented World

Common Scenarios That Alter Pressure

Understanding how and why pressure changes helps in diagnosing issues in refrigeration and HVAC systems.

Overcharging the System

Adding too much R34 can lead to excessive head pressure. The compressor works harder, increasing power consumption and potentially shortening its lifespan. Symptoms include:

- Discharge pressure exceeding 150 psi

- Frost formation on the condenser

- Overheating

Undercharging the System

Too little refrigerant means lower suction pressure and inadequate cooling. This can lead to icing of the evaporator coil and insufficient thermal exchange.

- Low-side pressure may drop below 40 psi

- Compressor runs longer

- System may short cycle

Heat Load Variation

External temperature influences internal pressure dramatically. On hotter days, the condenser has to work harder, and the head pressure naturally increases. A properly balanced R34 system adjusts through capillary tubes or expansion valves to maintain internal equilibrium.

Pressure-Temperature Relationship of R34

An essential part of system maintenance and diagnosis is referencing a pressure-temperature (P-T) chart. Though hypothetical due to limited data, a typical R34 P-T table would look like the following:

| Temperature (°C) | Saturation Pressure (psi) |

|---|---|

| -30 | 15 |

| -20 | 22 |

| -10 | 31 |

| 0 | 41 |

| 10 | 52 |

| 20 | 64 |

| 30 | 78 |

| 40 | 93 |

| 50 | 109 |

Note: These values are illustrative and based on estimated physical properties. Always consult certified data sheets for actual use.

How Pressure R34 Compares to Other Refrigerants

| Refrigerant | Operating Pressure (psi) | Environmental Impact | Flammability | Common Use |

|---|---|---|---|---|

| R134a | 35–145 | Moderate GWP | None | Automotive, Domestic AC |

| R410a | 110–400 | High GWP | None | Split AC, Commercial |

| R1234yf | 30–150 | Low GWP | Slight | Next-gen automotive |

| R34 | 45–135 (est.) | Medium | None | Research, Prototypes |

The pressure behavior of R34 is moderate, sitting comfortably between R134a and older CFCs. This makes it manageable for both system safety and performance, provided the refrigerant is handled within its design specs.

Maintenance and Safety Guidelines

Because pressure issues are often symptoms of deeper system malfunctions, maintaining optimal conditions requires a checklist approach.

Recommended Practices

- Annual pressure testing: Use accurate gauges to monitor static and dynamic pressure.

- Leak inspection: Fluorinated gases like R34 can escape from microcracks. Use halogen leak detectors.

- Oil compatibility: Ensure lubricant oils in the system are compatible with R34 to avoid corrosion.

- Recordkeeping: Maintain logs of pressure readings, maintenance dates, and refrigerant additions or removals.

Safety First

- Use gloves and goggles when connecting gauges.

- Ensure proper ventilation when recovering refrigerant.

- Never mix R34 with other gases unless specified—it alters pressure characteristics unpredictably.

Regulatory Outlook and Environmental Positioning

Though R34 was not globally adopted, its theoretical development played a crucial role in shaping refrigerant policy. Pressure behavior influences emissions, and pressure-induced leaks are a major source of environmental harm in commercial systems.

Today’s refrigerants are judged not only on performance but also:

- Ozone Depletion Potential (ODP): R34 has low ODP.

- Global Warming Potential (GWP): Medium compared to modern low-GWP gases.

- Lifecycle Efficiency: How efficiently it performs over years of use.

Future of Pressure Optimization

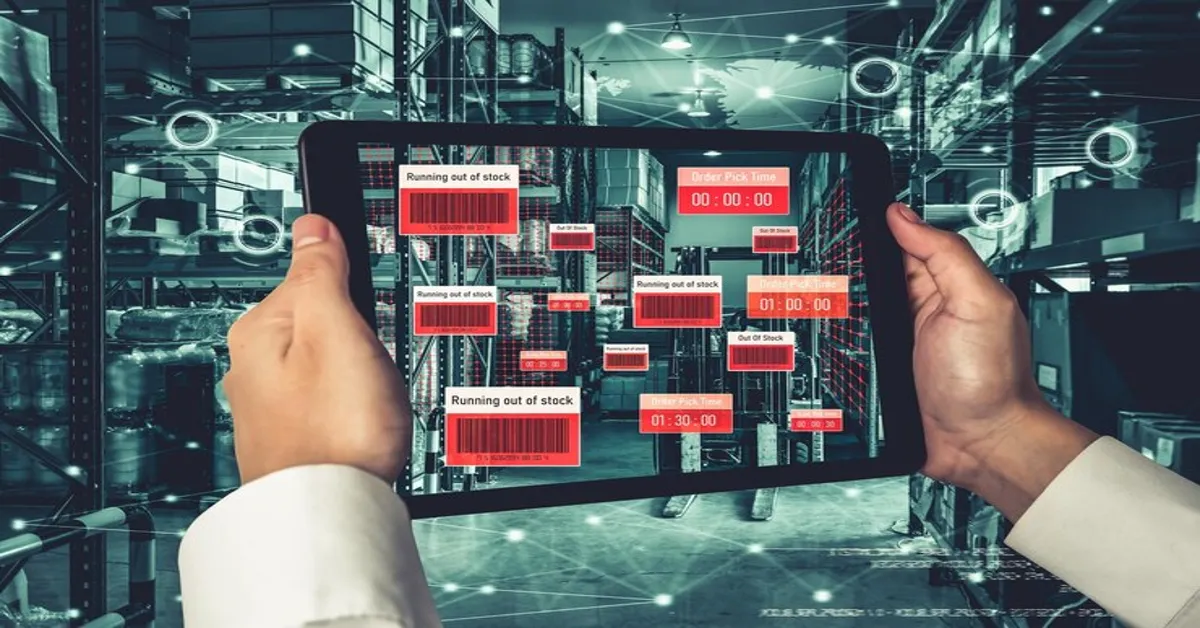

In modern HVAC and cooling systems, the control of refrigerant pressure is no longer manual alone. Systems increasingly use:

- Digital pressure sensors

- Variable-speed compressors

- Adaptive expansion valves

These technologies reduce the environmental impact and improve energy efficiency. If R34 were to be re-engineered for modern use, it would need to integrate with these smart systems, adjusting pressure in real time based on demand and ambient conditions.

Conclusion

“Pressure R34” isn’t just a keyword—it’s a gateway to understanding a broader ecosystem of refrigerant behavior, system performance, and environmental responsibility. While R34 itself may remain on the margins of mainstream use, its study provides critical lessons in how pressure management shapes thermal systems. As HVAC technology advances and regulatory scrutiny intensifies, the ability to understand and manage refrigerant pressure will become an even more essential skill for technicians, engineers, and decision-makers alike.

From lab experiments to niche installations, R34’s pressure behavior provides a controlled, accessible model for exploring thermodynamics, diagnostics, and safe maintenance. And in doing so, it continues to influence how we think about sustainable, efficient climate control.

FAQs

1. What is Pressure R34 and how is it used in refrigeration systems?

Pressure R34 refers to the behavior and management of refrigerant R34’s pressure within a closed-loop refrigeration or HVAC system. Though not widely commercialized, R34 was explored in prototype cooling systems for its stable pressure characteristics and relatively moderate environmental impact. Understanding its pressure profile is crucial for system design, diagnostics, and maintenance.

2. What are the typical operating pressures of R34 in a functioning system?

In a standard operating environment, R34 typically exhibits a low-side (suction) pressure between 45–60 psi and a high-side (discharge) pressure between 110–135 psi, depending on ambient temperature and system load. These values may fluctuate in response to external conditions or mechanical factors.

3. How does ambient temperature affect the pressure of R34 refrigerant?

As ambient temperature increases, both suction and discharge pressures rise. For instance, a rise from 20°C to 40°C can elevate high-side pressure by over 30 psi. Accurate pressure readings must be contextualized with temperature to determine if the system is operating normally.

4. What happens if an R34 system is overcharged or undercharged?

Overcharging leads to excessively high pressure, risking compressor failure and inefficient cooling. Undercharging results in low suction pressure and insufficient refrigerant flow, which can cause coil freezing or erratic cycling. Both conditions reduce system efficiency and lifespan.

5. Is R34 refrigerant environmentally friendly compared to newer alternatives?

R34 has a moderate global warming potential (GWP) and low ozone depletion potential (ODP), making it safer than older refrigerants but less sustainable than next-generation options like R1234yf. It is not widely used today but serves as an important transitional refrigerant in environmental studies.